About this article

In the context of supply chain management, demand forecasting involves predicting future demand for products or services to ensure that the right quantity of goods is produced, delivered, and available to meet customer demand. Accurate forecasting in supply chain management is essential to optimize inventory levels, reduce costs, and improve customer service. Forecasting methods commonly used in supply chain management include quantitative methods, such as time-series analysis, regression analysis, and causal modeling, as well as qualitative methods, such as market research and expert opinion. However, supply chain forecasting is a challenging task, as it requires dealing with multiple sources of variability, such as seasonality, trends, and unexpected events, such as natural disasters, economic downturns, or pandemics. Therefore, forecasting in supply chain management involves not only using the right methods and tools but also understanding the business context, interpreting the data correctly, and incorporating human judgment and experience to make accurate predictions and informed decisions.

Forecasting in Supply Chain Management

In the fast-paced world of supply chain management, where efficiency and agility are paramount, the ability to accurately predict future demand for products and services is indispensable. Demand forecasting serves as the cornerstone of effective supply chain planning, ensuring that the right quantity of goods is produced, delivered, and available to meet customer needs. In this article, we delve into the significance of demand forecasting within the context of supply chain management, exploring its methods, challenges, and critical importance in optimizing operations.

Understanding Demand Forecasting

Demand forecasting is the process of predicting customer demand for products or services over a future time horizon. In the realm of supply chain management, accurate forecasting is essential for various reasons:

-

Optimizing Inventory Levels: By forecasting demand accurately, businesses can maintain optimal inventory levels, avoiding overstocking or stockouts that can lead to increased carrying costs or lost sales opportunities.

-

Reducing Costs: Efficient demand forecasting enables cost savings by streamlining production schedules, minimizing excess inventory, and optimizing transportation and storage expenses.

-

Improving Customer Service: Meeting customer demand promptly and efficiently enhances satisfaction and loyalty, fostering long-term relationships and a positive brand reputation.

Seven Steps in Forecasting

- Determine the use of the forecast

- Select the items to be forecasted

- Determine the time horizon of the forecast

- Select the forecasting model(s)

- Gather the data

- Make the forecast

- Validate and implement results

Methods of Demand Forecasting

Supply chain professionals employ various methods to forecast demand, each suited to different scenarios and data availability:

-

Quantitative Methods: These involve statistical techniques to analyze historical data and identify patterns that can inform future demand. Common quantitative methods include:

-

Time-Series Analysis: This method examines historical data to identify recurring patterns, such as seasonality or trends, and extrapolates them into the future.

-

Regression Analysis: Regression models establish relationships between demand and relevant factors such as price, marketing efforts, or economic indicators, aiding in forecasting.

-

Causal Modeling: Causal models incorporate external factors like market conditions, consumer behavior, or advertising campaigns to predict demand changes.

-

-

Qualitative Methods: Qualitative forecasting relies on expert judgment, market research, or customer feedback to anticipate demand in situations where historical data may be limited or unreliable. Expert opinions and market insights play a crucial role in qualitative forecasting, especially in volatile or rapidly evolving markets.

METHOD OF MOVING AVERAGES

Three Common Measures of Error

Karl Pearson's Coefficient of Correlation

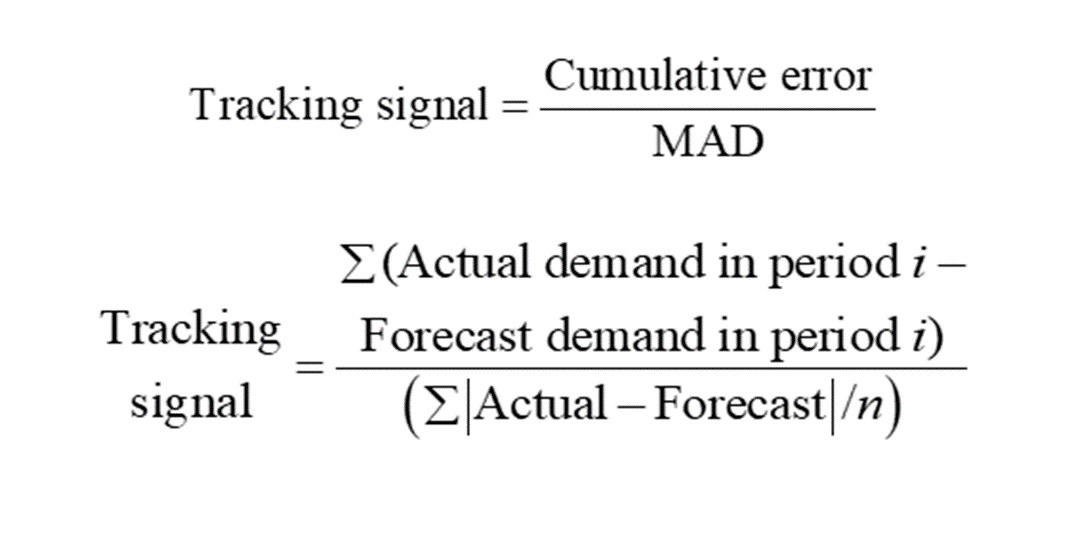

Monitoring and Controlling Forecasts

Rule: If Tracking Signal > 3.75 then there is persistent under forecasting. On the other hand, if this is less than -3.75 then, there is persistent over-forecasting.

Challenges in Supply Chain Forecasting

Forecasting demand in supply chain management presents several challenges, including:

-

Variability: Supply chains are subject to various sources of uncertainty, including demand fluctuations, supplier reliability, and external disruptions like natural disasters or geopolitical events.

-

Complexity: Modern supply chains are intricate networks involving multiple stakeholders, making it challenging to capture and integrate data from diverse sources effectively.

-

Dynamic Environment: Consumer preferences, market trends, and competitive dynamics evolve rapidly, necessitating agile forecasting processes that can adapt to changing conditions.

Conclusion

In conclusion, demand forecasting is a critical function in supply chain management, enabling organizations to anticipate and respond to customer demand effectively. By leveraging a combination of quantitative and qualitative methods, supply chain professionals can develop robust forecasting models that account for variability and uncertainty, enabling informed decision-making and strategic planning. In an increasingly competitive and dynamic marketplace, accurate demand forecasting is not just a competitive advantage but a prerequisite for sustainable growth and success.

References

-

Chopra, S., & Meindl, P. (2016). Supply Chain Management: Strategy, Planning, and Operation (6th ed.). Pearson Education.

-

Mentzer, J. T., Stank, T. P., & Esper, T. L. (2008). Supply chain management and its relationship to logistics, marketing, production, and operations management. Journal of Business Logistics, 29(1), 31-46.

-

Montgomery, D. C., & Runger, G. C. (2018). Applied Statistics and Probability for Engineers (7th ed.). John Wiley & Sons.

-

Tang, O., & Musa, S. N. (2011). Identifying risk issues and research advancements in supply chain risk management. International Journal of Production Economics, 133(1), 25-34.

-

Wilson, J. R. (2002). Best practices in demand forecasting. Journal of Business Forecasting Methods & Systems, 21(3), 11-14.

Post a Comment

Only members are able to send comments