Forecasting in Sup ... Forecasting in Supply Chain Management

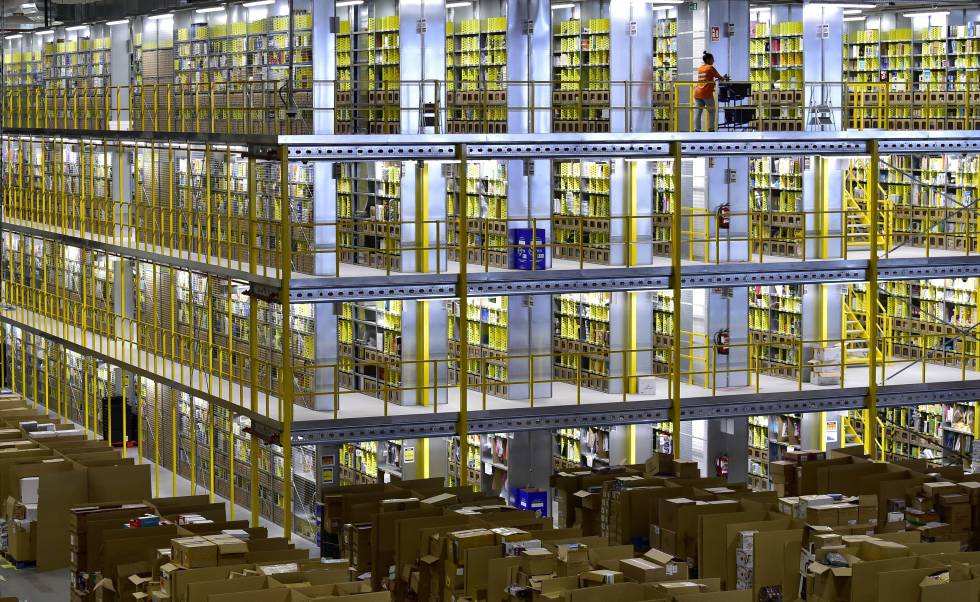

In the context of supply chain managemen ... In the context of supply chain management, demand forecasting involves predicting future demand for products or services to ensure that the right quantity of goods is produced, delivered, and available to meet customer demand. Accurate forecasting in supply chain management is essential to optimize inventory levels, reduce costs, and improve customer service. Forecasting methods commonly used in supply chain management include quantitative methods, such as time-series analysis, regression analysis, and causal modeling, as well as qualitative methods, such as market research and expert opinion. However, supply chain forecasting is a challenging task, as it requires dealing with multiple sources of variability, such as seasonality, trends, and unexpected events, such as natural disasters, economic downturns, or pandemics. Therefore, forecasting in supply chain management involves not only using the right methods and tools but also understanding the business context, interpreting the data correctly, and incorporating human judgment and experience to make accurate predictions and informed decisions.

What is safety sto ... What is safety stock?

A strategic supply chain management syst ... A strategic supply chain management system is vital to the success of any product based operation. It can lead to increased customer satisfaction, reduced operational costs, and steady cash flow for your business.

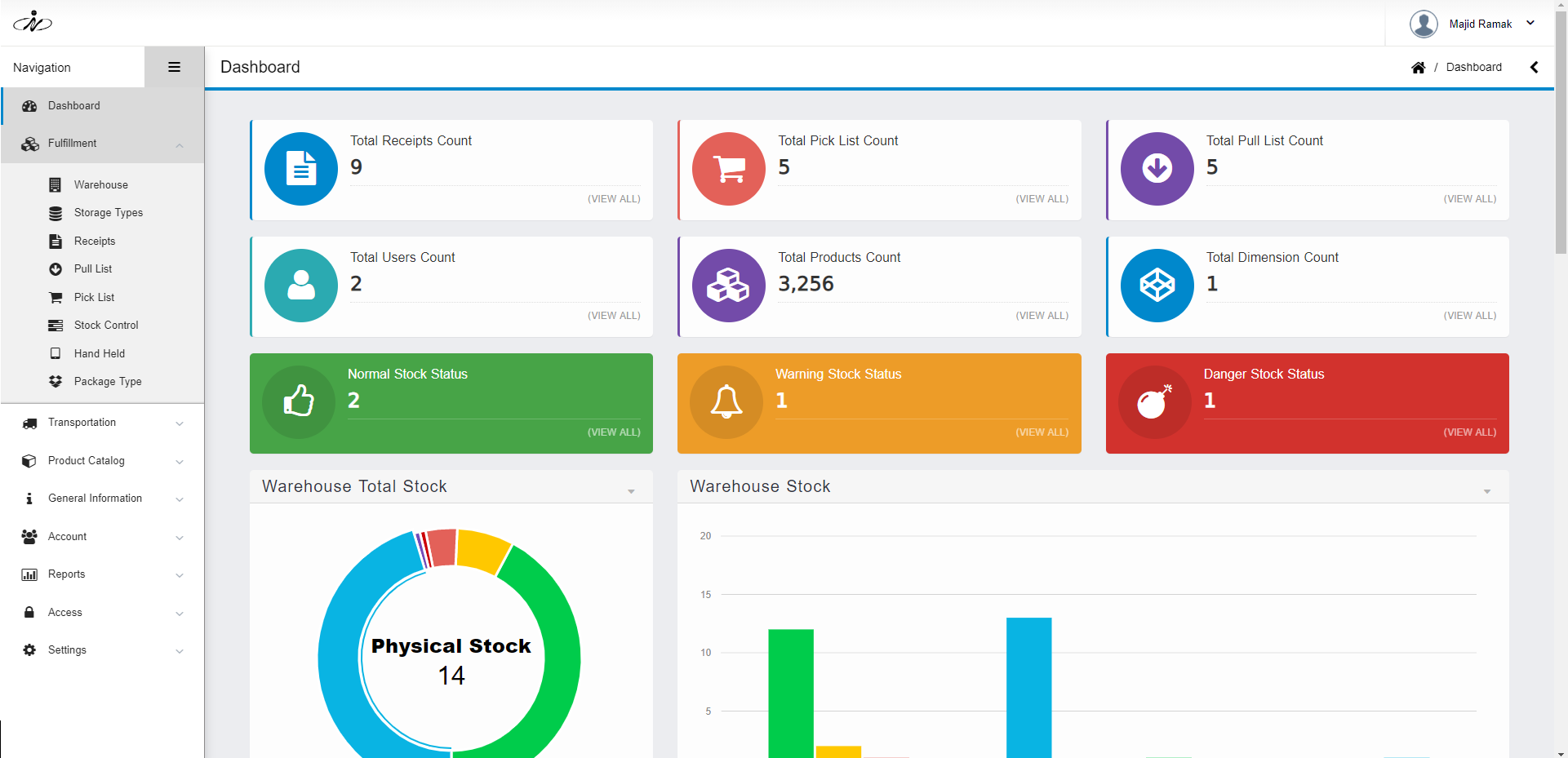

Logistic Execution ... Logistic Execution Solution

Nowadays, due to the pandemic and its im ... Nowadays, due to the pandemic and its impact on increasing the demand for software platforms, we started to prepare logistics execution solutions to provide the required companies. For more information, you can visit http://lesolution.org/

Staging Area

Staging areas are used for the interim s ... Staging areas are used for the interim storage of goods in the warehouse. They are located in close proximity to the doors assigned to them. You can define staging areas for different purposes and even simultaneously for multiple purposes.

Serial & Batch Sto ... Serial & Batch Stock Management

Batch and serial stock management are tw ... Batch and serial stock management are two different concepts to control and track stocks inside and outside the warehouse and they can the ability to monitor and prioritize stocks.

Challenges Part 1

In recent years, we have faced many chal ... In recent years, we have faced many challenges and we have tried to be able to find a suitable and optimal solution for each of these challenges, a solution that will increase productivity. In this collection of articles, I intend to talk about the challenges faced, look into how to deal with them, and effect of actions taken on specific KPIs.

Recommendation-bas ... Recommendation-based Storage Algorithm

On of the main concerns that I have face ... On of the main concerns that I have faced during passed years in warehouse management concept was designing stowing algorithm based on AI concepts to manage warehouse storage locations and reduce the staffs covered distance inside the warehouse in picking process. In this article we are trying to discuss this further.

Acceptable Quality ... Acceptable Quality Limit (AQL)

One of the most important matters in inb ... One of the most important matters in inbound process is ensuring the health and the originality of the goods in the fastest possible way, in this article we are trying to speed up the inbound process by AQL concept (Acceptance Quality Limit).

Stock Taking

Stock taking is the counting of on-hand ... Stock taking is the counting of on-hand inventory. This means identifying every item on hand, counting it and summarizing these quantities by item. In this article we are trying to discuss on stock taking methods and algorithm in Warehouse Management Systems (WMS).

Putaway Process Im ... Putaway Process Importance

Putaway is one of the most important and ... Putaway is one of the most important and vital topics in the field of warehousing. Due to the importance of resource management and finding optimal algorithms in various fields and using the experiences of great people in this field, more mature processes can be designed.